Does your transceiver power supply run a little too hot?

Mine sure does, but I found a simple solution that keeps things cool without a lot of whoosh noise.

Hot Box PS

I have a CSi/SPECO 13.8 Volt 18 Amp model which serves my puny little 100 Watt station very well.

This power supply is a linear regulated type with plenty of pass transistors in the back embedded in a nice large heatsink. There are two problems: the heatsink fins are oriented horizontally and the heatsink gets far too hot to touch after being on for a while.

I know… I know many of you are thinking my 18 amp power supply is a little underrated for a 100 Watt station and that is the reason for the excessive heat. You may have a point, but the situation here is this power supply gets way too hot to touch with no load on it. It takes quite a while, but the heat eventually builds up and reaches an equilibrium point where you simply cannot touch it for more than a few seconds. I never measured the temperature so cannot be sure how hot it really got. It was just… hot.

Tough transistors need a break

As a circuit designer I am well aware of how much punishment good final transistors can take (some have max junction temperatures of 275 C!!!). However, cooler running is always going to increase reliability of all electrical components.

It’s a shame the heatsink is oriented horizontally as the system would probably be measurably cooler with chimney effect air flow. I was not willing to put the power supply on its side.

So what to do…

Add wind

Adding a fan to move air across the heatsink was an obvious necessity. I considered AC fans and 12 Volt fans, but found them to be quite loud. They work fine, but made far too much whoosh noise. They work so well they blow a great deal of air across the heatsink, but I wondered if I really needed so much air flow to get my high temperature under control.

Thermal experience from Aerospace Industry

As it turns out I had a similar issue back in the 1990s when faced with defending the movement of a heatsinked 7905 regulator connected to -12 Vdc from just above some cooling fans to a few inches away. The original designers were concerned my moving the regulator away from the direct blast of the fans would be too costly in cooling performance.

The regulator was dissipating several watts of power so this was a reasonable question. I devised a test to determine the cooling performance of air flowing past a heat sink vs. the fan-heatsink distance.

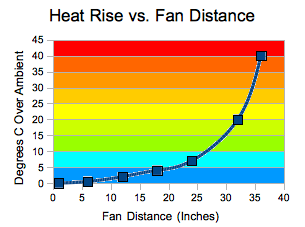

I moved the regulator circuit with its heatsink out of the cooling cage and into still air. I placed a thermocouple on the heatsink. I obtained a muffin fan and wired it up to a power source. While holding the fan various distances from the regulator, I made the following observations.

- Fan Off:

- The temperature of the heatsink climbed steadily past 50 degrees C above ambient reaching dangerous levels in a short time terminating this test.

- Fan On and held 1 inch from the heatsink:

- The temperature of the heatsink remained at room temperature.

- Fan On and held 6 inches from the heatsink:

- The temperature of the heatsink was, maybe, about 1/2 degree above ambient.

- Fan On and held 12 inches from the heatsink:

- The temperature was about 2 degrees above ambient.

- Fan On and held 18 inches from the heatsink:

- The temperature was about 4 degrees above ambient.

- Fan On and held 24 inches from the heatsink:

- The temperature was about 7 degrees above ambient… O come on how can this be still cooling the regulator at two feet?

- Fan On and held 32 inches from the heatsink:

- Temperature about 20 degrees above ambient.

- Fan On and held about 36 inches form the heatsink:

- Temperature about 40 degrees above ambient and varying quite a bit.

This data is better shown in the graph below…

The slightest breeze cools a lot

This revealing test shows fin heatsinks are actually very good at coupling heat to the air with remarkably little airflow. However, there has to be at least some airflow to prevent heat saturation at the heatsink air boundary and that is, apparently, where you realize most of the cooling benefit.

All I needed was some airflow, not a hurricane.

All the fans I found all worked great, but made a lot of noise. I thought about creating a simple little regulator circuit to knock down the 13.8 Vdc to something lower and slower.

24V fan on 13.8V

With the goal of operating a fan lower than its voltage rating I remembered some DC busses run at 24 volts or so and have plenty of compatible products including fans.

So I decided to purchase a 24 Vdc fan and run it off the 13.8 Vdc power supply voltage to slow it down to a slight breeze. Avoiding the step down regulator by simple component choice kept things straightforward.

Here is the simple install of my 24 volt fan running “slow.”

I found some twisted pair cable and used that to connect the 24 Vdc fan to the power supply’s output via a couple of banana plugs. The green banana plug is not related to the fan, but illustrates the ease of adding more connections by stacking the banana plugs. No RigRunners or Anderson Power Poles needed for this low current load.

Results?

With the 24 volt fan running on 13.8 Vdc, it quietly and gently provides airflow across the horizontal fins of the power supply’s heatsink. This airflow works so well you can barely feel any rise in temperature when touching the heatsink. Success!

The final issue I had with this arrangement was the fan vibrating my desktop thereby generating audible noise. This was easily solved by putting a loosely folded piece of paper underneath the fan to serve as a vibration isolator. It works FB. No its not earthquake proof, but functional.

Conclusion

Power supplies, especially economy models like mine, often omit fans and rely on the very high temperature rated components to just take the abuse. This can work, but the addition of a simple 24 Vdc fan running slow on the supply’s 13.8 Vdc output provides more than enough cooling capacity to keep the output transistors at a far lower temperature than without. Cheaper insurance is hard to find.

Cool your power supply today… It will love you for it.

This is something I also found out, as I have a 13.8V power supply for my ham radios, one of the radios now has 3 x 24v 40mm fans bolted to the heat sink, I also have a cheap made in china temperature switch, so it displays the temperature, then switches the fan on at 35C and cools the radio down, works very well. Radio Pa never gets above 40C at most 😉