New HF Mobile Antenna Design

While working on a new HF mobile antenna concept, I reached the point to profile some loading coil concepts. I try to design assemblies with off the shelf products so others might try the concept with relative ease. Unfortunately the supply of coils suitable for an HF mobile center loaded antenna assembly are few and far between. I missed the ball with the BugCatcher series of well designed coils proportioned to maximize efficiency. Fortunately I found Wolf River Coils (WRC).

Wolf River Coils

Wolf River Coils specializes in relatively narrow coils for HF use with the following attributes.

- Diameter: About 1.7 inches (~42 mm) diameter.

- Conductor: Stainless steel wire for the coil conductor inlaid into a shallow groove in the tubular form.

- Inductor topology: A general theme of long vs. wide inductor dimensions. This trades efficiency for a sleek profile.

- Product line breadth: Some models are retrofit components for other commercial antennas.

- Mobile: Some models include typical 3/8-24 mobile antenna interconnections.

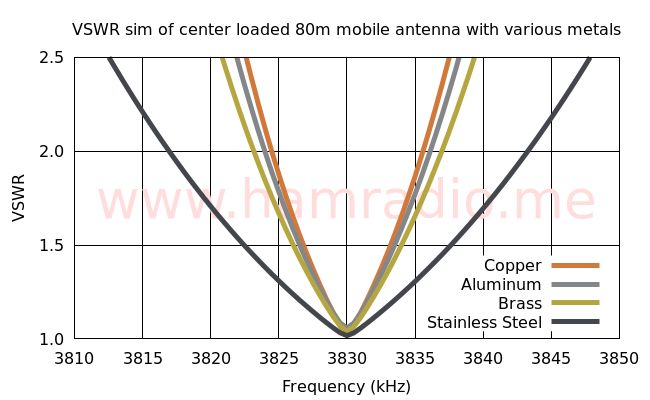

As many of you know, long and narrow inductors aren’t as efficient as fat and short designs. As well stainless steel is quite a bit less conductive than other choices… noticeably so in things like inductors as this simulation of the WRC coil in a mobile 80m antenna with various conductors suggests…

Thin… stainless steel… lower Q. Three strikes you say? Not so fast because at least you can order their products and, in my example, take delivery in just two days. In stock counts A WHOLE LOT in my book.

Another post will delve into the engineering of my prototype antenna system and the coil requirements. Suffice it to say my modeling shows the longer Wolf River Coils reach into the 75m band reasonably well and the clearly measurable stainless steel cost to efficiency isn’t a show stopper.

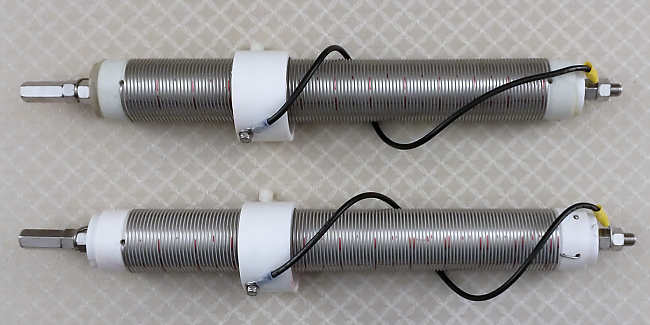

Super Bullet 1000 vs. Silver Bullet Platinum 1000

If you read the various antenna design watering holes concerning inductors and their non-conductive forms, you will likely learn the horrors of the dielectric material softening in the strong fields leading to mechanical failure. So guess what… the longer coil design from Wolf River comes in two forms… apparently the later variant handles more power leaving one to wonder the difference. The Wolf River FAQ and some of the forums where they’ve made announcements offer no clues. I knew I needed the longer SB 1000 coil length. Ever inquisitive, I purchased both. Here they are…

The sliding coupler (that bypasses turns from the top down) has a robust stainless steel spring contact that holds firm.

Here are closer views of the contact.

Kung Fu grip

This contact system maintains a firm hold to the coil windings and requires quite a pull or push to change position. The nylon screw helps secure it in place, but seems to be secondary to the stout force provided by the metal to metal contact.

I’m very impressed how well the coil wire holds place on the cylinder form, hence, validating the specifics of their groove technique mentioned on their web site…

“We groove our coil specifically for proper spacing and placement of our high quality heavy duty stainless steel wire. We shave 1/64ths off the core measured by using a caliper.”

The grooves are deep enough to hold the windings in place during the rather large force during coupler adjustment, but not too deep to complicate fabrication. A nice balance. I have the Vertical Base Replacement Coil as well and it also has the same mechanical benefit. I chuckled at the “using a caliper” comment. If this impresses the amateur radio community… we’re in trouble.

Veering back to the two specific ‘SB1000’ mobile coil products, the rather brief description of both suggests they are electrically the same. Initial views confirms they are “nearly” identical with some obvious differences. Let’s compare a few attributes.

Overall Length

The two models have similar, but not the same length. This view shows the difference in overall length…

- Silver Bullet – overall length 414 mm (16.3″)

- Platinum – overall length 406 mm (16.0″)

Number of turns and winding length

One might think the higher power version of the same product would have the same winding characteristics. They are close, but not quite the same.

- Silver Bullet – 123 and 1/2 turns over a coil length of 284 mm (11.18 inches) – about 11 turns per inch

- SB Platinum – 122 turns over a coil length of 281 mm (11.06 inches) – also about 11 turns per inch

The winding pitch is almost the same, but holding the two windings together you can see the drift in pitch. This likely won’t change performance much, if at all, but machining a thread should be a reliably repeatable operation in any modern shop. #surprised

Weight (mass)

One is slightly heavier in weight…

- Silver Bullet 1000 – 646 g (1 lb, 6.8 oz)

- Silver Bullet Platinum 1000 – 678 g (1 lb, 7.9 oz)

A close look at the ends of each provides some visual clues to material differences.

Let’s zoom in a bit.

The slightly heavier Platinum model looks more like fiberglass.

Power handling

- Silver Bullet 1000 (website) – 100 watts SSB, 50 watts CW, 20 watts digital

- Silver Bullet 1000 (instruction sheet) – 100 watts SSB, 50 watts CW, 25 watts digital

- Platinum 1000 (website & instruction sheet) – 500 watts SSB, 300 watts CW, 100 watts digital

“Hmmm” is a reasonable reaction. These carefully defined and tweaked power limits suggests they really mean it.

A lesson from the past

Successful HF loading coil products of the past have kept the windings well away from any mechanically supportive center structure. Perhaps Wolf River Coils has found a way to alleviate the need for that separation with a material that absorbs less energy from the strong fields. Or perhaps it absorbs the same energy, heats the same, but simply handles the rise in temperature without softening. Maybe the stainless steel wire actually has I^2R heating. Or both! Either way I am thrilled they have addressed the issue with the Platinum option. Piece of mind is well worth the extra cost for this ham.

One example where “heat” matters

KN3A writes about his outdoor radio activity…

Quick activation tonight. 40 QSO’s in just over an hour. Was disappointed to see this though. CW/Phone at 100 watts for that short period of time and the 213 inch whip on the top should not have done this. Left message for WRC to call me tomorrow. Thanks for the QSO’s tonight. 73 de KN3A.

Excerpt and photo used with permission from KN3A.

It seems Wolf River Coils’ creation of a sturdier version of the Silver Bullet 1000 is both timely and prudent.

More about coil windings

Let’s review some key teachings from page 52-54 of Everything You Forgot to Ask About HF Mobileering [1]

- PVC may be okay. No gray, no foam filled. Test with microwave if unsure.

- Choose wire #16 (1.29 mm 0.051″) diameter or larger. The .062″ diameter of the WRC coil meets this requirement.

- Made with solid copper. WRC makes the case for stainless steel on their web site, however, much depends on which variant they use. Thankfully, it doesn’t appear to have any magnetic properties (yes I checked) like some stainless steel variations… that would be detrimental to skin depth hence RF conductivity.

- Wind the wire tight. Yeah the WRC is pretty darn tight and sound, as is the the entire mechanical assembly.

- “When Schedule 40 PVC is used for the coil form, running over 300 watts gets a little dicey. At 600 watts of Amtor the PVC may fold over like a wet noodle after a few lines of text.” Hmmm.

- “Space the windings at least one wire diameter.” At 11 turns per inch, the WRC winding gap of 0.027″ does not achieve this suggestion.

The WRC models break a few of these rules, but perhaps their specifications are a suitable compromise for convenience. Hence, I will dig deeper in a future article. For now the above guidance provides a little insight into concerns that may lead to coil failure.

Cost

As of Pi Day 2022 (March 14, 2022)…

- Silver Bullet 1000 – $75

- Silver Bullet Platinum 1000 – $170

If you are a QRP operator, the lower cost coil should be good for you. On the other hand, everyone else should not dance so close to the roof’s edge and drop the extra coin on the Platinum’s much more generous power handling capability. I mean really… do you want to hear those jokes?

Possible improvements?

It seems the base material for the Platinum is fiberglass tube of 1-5/8 diameter. Let’s explore some options keeping the same 11 TPI and same wire with these various McMaster available tube sizes and winding counts…

- Approximate Baseline: 121 turns, 1.628″ winding diameter, 11″ length yields about 83 uH (based on this) – winding length about 619 inches (~6 ohms dc) Is it any wonder why the published WRC bandwidth is oddly wide?;

We take a break from this list to do a double take on that calculated winding resistance… SIX OHMS!?! That’s what the online calculators suggest. I had to see this for myself. I headed to the lab with the SB Platinum for measurement and, sure enough, just over six ohms! Let’s see if we can tame that a bit.

- More inductance option 1: 121 turns, 2.003″ winding diameter, 11″ length yields about 123 uH… more easily reach the CW portion of 80m – winding length about 761 inches (~8 ohms dc);

- Shorter option 2: 88 turns, 2.003″ winding diameter, 8″ length yields about 87 uH… a shorter version of the baseline – winding length about 554 inches (~5.5 ohms dc);

- Fatter and shorter option 3: 55 turns, 2.783 winding diameter, 5 inch length yields about 94 uH – winding length about 481 inches (~4.7 ohms);

You see where I’m going with this.

Heater wire?

With stainless steel ‘s forty-four (44!) times dc resistance over copper at dc, who knows what skin depth effects are at rf. It can only get worse. Riggins (#44) is a great memory, but doesn’t help much in antenna resistance… unless low Q is your thing. Currents for electrically short HF aerials at 100 watts run a couple to several amps through the coil… I’ll leave it to the reader to calculate the I^2R heating loss of each scenario. Thoughts and prayers for poor PVC when used as a form for this heater element. Fiberglass to the rescue I suppose.

The wish list

Here’s the dream SB Platinum coil…

- Option 4: 38.5 turns, 3.503″ winding diameter, 3.5 inch length yields about 90 uH – winding length about 423 inches (~4.2 ohms)

Result? A nice squarish inductor that somewhat mitigates the penalty of using stainless steel wire while preserving its mechanical advantages. It would be super nice to widen the gap between windings to at least one wire diameter. Let’s see… at 8 TPI…

- Option 5: 48 turns, 3.503″ winding diameter, 6″ length yields about 93 uH – winding length about 527 inches (~5.2 ohms dc)

- Option 6: 40 turns, 3.753″ winding diameter, 5″ length yields about 84 uH – winding length about 472 inches (~4.7 ohms dc)

Phat!

Conclusion

Tight

I much like the overall mechanical design achievement of the WRC products. The coupler slides with effort while maintaining an obvious and tight grip on the windings. Solid.

The acid test

More research is forthcoming with these coils in my mobile installation. Expectations of efficiency vs. copper properly managed (44!?!), I have hope for a usable HF mobile system featuring the Platinum coil. My approach has interchangeable loading coils allowing for direct and quick comparison with other coil options. Candidates include more efficient custom designs.

New coil kid on the block?

With the loss of the Texas BugCatcher product line, the supply of coils for HF mobile use is limited. Whereas the screwdriver choices are ample, the less expensive simpler options seem rare. Therefore, let’s see how well the WRC products hold up. I hope this brief article helps answer the question of the differences between the Silver Bullet 1000 and Silver Bullet Platinum 1000 coils form Wolf River Coils.

References

- Johnson, D. (1997). Everything you forgot to ask about Hf mobileering. Worldradio Books.

You can calculate coil inductance and Q with this:

http://ham-radio.com/k6sti/coil.htm

You can calculate SS wire skin-depth and skin-resistance, at various frequencies, with calculators on Owen Duffy's website: https://owenduffy.net/calc/SkinDepth.htm https://owenduffy.net/calc/WireDcResistance.htm

Data for 1 meter of 2mm (#14) SS (#316) ) wire at 7mHz yields 0.8 ohms.

Looks like you can buy the Texas BugCatcher coils here: https://www.mtcradio.com/texas-bugcatcher-hf-mobi…