PolyPhaser – the Sears of Lightning Protection

You have to have lived in the deep woods with complete disconnect from society (like that fellow in Maine living off the land for over two decades) to not know about Polyphaser (if you’re in the radio biz at least). Many a ham and professional has a copy of The Grounds for Lightning detailing the perils of properly handling the surge from lightning events. I bought into the Polyphaser approach in the 1990s with a successful rollout of protection for the Navy Prototype Optical Interferometer on Anderson Mesa in Arizona.

Other than dabbling around the house a bit, I’ve not had recent professional exposure to the Polyphaser line of products until now.

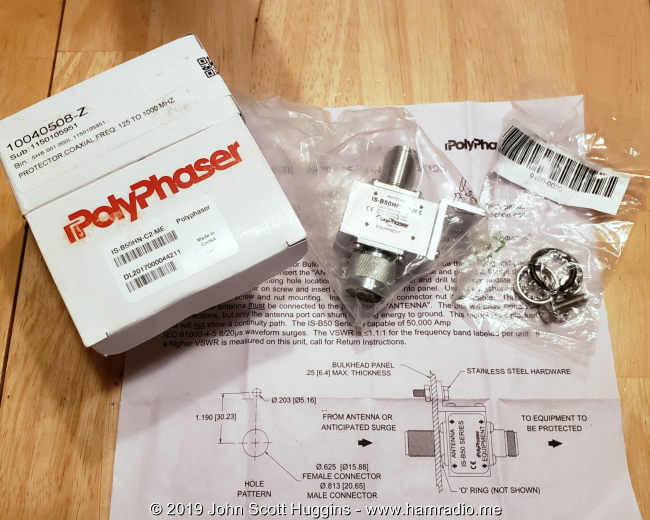

Recent purchase of PolyPhaser IS-B50HN-C2-ME

I found an Ebay store with a large number of PolyPhaser IS-B50HN-C2-ME protectors. I don’t like the male connector on what should be the equivalent of a bulkhead feed through, but hey at $28 the price was right. I scratched my head on this because they should cost quite a bit more, but here it is nonetheless…

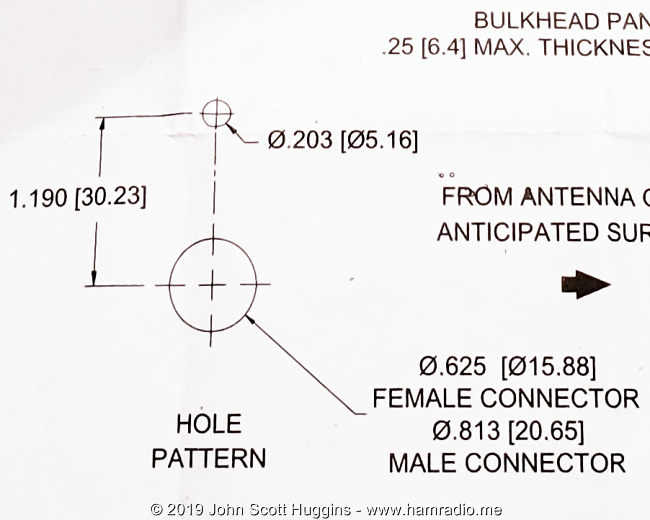

I made a rack grounding panel that matches the hole pattern you see in the lower left.

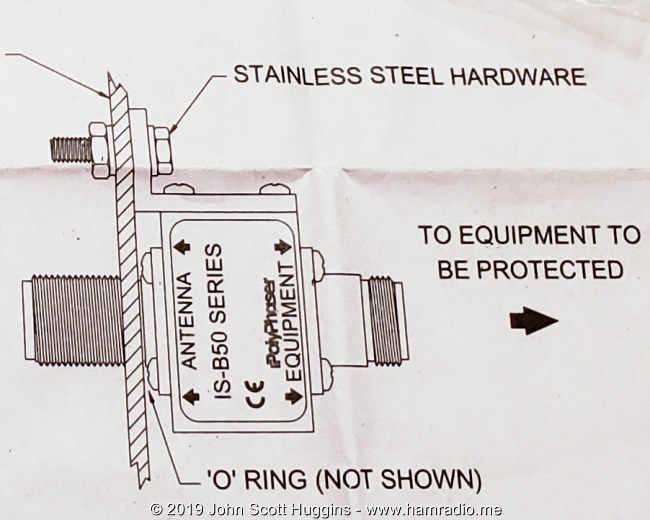

This method of attaching protection devices isn’t without precedent as this grounding panel product from none other than Polyphaser attests…

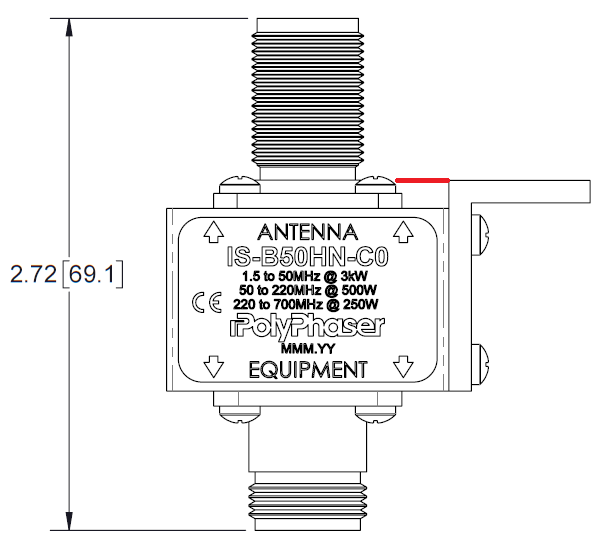

I examined the lower right drawing for instructions on how to mount this in my panel.

Highlights include:

- The L-shaped tab mounts flush to the panel.

- The body of the protector and the screw heads float above the panel, but just barely.

- The “O” ring provides a measure of sealing for air blockage.

Let’s see how this worked out.

With hardware not yet tight, we can immediately see a problem here. The screws securing the N connector to the main body protrude past the plane made by the L shaped bracket mounting surface. Thus the foot doesn’t make good contact… definitely not in line with the usual PolyPhaser dictate that includes compressing a bit of anti-oxidant compound between bracket and panel.

Let’s see an edge on view.

Let’s tighten the hardware and see what that does.

Leading to…

Thoughts

I showed this to a machinist friend who immediately offered to “slot” the L tab mounting screws to allow relative adjustment between bracket and body. That’s all well and good, but really why should I have to worry about this? Consider if I purchased these in good faith and hauled them up with other supplies to the mountain top. No machinist there to help force fit supposedly factory fresh PolyPhaser components to the system panel.

Mechanical fixes abound, but now I have to wonder if this is some sort of counterfeit product with poor workmanship in more than the mechanical. Worse yet, perhaps this is what PolyPhaser has become. I don’t have an easy way to know. A reader of the Repeater Builder Forum highlights this drawing from the Polyphaser web site info page…

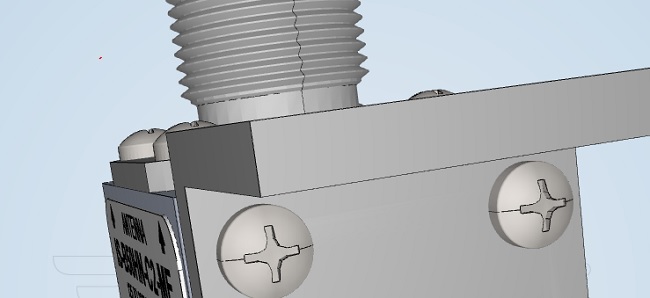

I added the red line to extend the plane of the tab to the screws. If the portrayal in the PDF reflects reality, the problem appears to be in design, not just QC. Looking to the 3D STEP file on their site we see this…

This also shows the screws protruding into the plane of the mounting tab.

Conclusion

This totally sucks man. You place your trust in a particular company’s products and design a panel to accommodate said company’s product per THEIR OWN INSTRUCTIONS, then this happens and you’re left wondering about misplaced trust, counterfeits, etc.

At least I only purchased one. The Ebayer has a lot of these to sell.

I was ready to buy a few more, but now am reticent. At least it appears Polyphaser itself has this design flaw built in… if we are to trust their datasheet and 3D CAD model.

I messed with the screws on the one I have to see if I can reposition the L bracket with respect to the protector body, but the problem persists. Potential fixes include:

- Adaptor: Shim the mounting tab to ensure entire area is available for conduction.

- Modify my design: Adjust my panel design to accommodate the screw head protrusion into the panel surface plane. Ugly.

- Modify Polyphaser in the field: Replace the panel facing screws in the Polyphaser with thin-head screws. Should not be required, but likely is the best option.

It’s an amazing time when you finally get to put stuff together and you find lurking issues.

You can change the direction the bracket is mounted on the PolyPhaser. But the screws or heads might strip out, as the are tightened.

That is how they are designed, but those are designed to be placed vertically on a grounding bracket that has a 90 bend where the polyphaser mounts.

I am using many of these but I mount mine on the grounding panel, just after the cable enters the building.

A flat washer, like a fender washer, could be used on the bracket bolt to provide extra clearance for the screw heads. This might affect the O-ring seal, but it could be used without modifying (replacing fasteners) the device itself.

A call to PolyPhaser would get an answer. They might ask you who was the Ebay supplier, or even have you send them yours. I can tell you there are counterfeits of most every RF component. I have found counterfeit parts supplied by a reputable supplier who had a dirty buyer who substituted China counterfeits. We banned the company.

And if its a legitimate part, you got a deal and a pennys worth of flat washers would solve the clearance problem.

I have contacted PolyPhaser and they seemed quite surprised. They had to accept their current production documentation, CAD data and my example all agree and show a screw head intrusion problem. Their QC has been notified. I'll update the article with their response once received.

Heh, I found this looking for polyphaser installation photos and had to chuckle.

I have installed hundreds of these from my time as a radio tech and I have to say *ALL* of the ones I have seen in that formfactor have gone in exactly as you have identified, with the screws forcing the mounting crooked.

So likely just desperately in need of updating some documentation.

I just had a bag of brass washers to keep the flange mounted flush and all was good.

We always installed with a helping of noalox anyway just because we were never sure if someone gave us a crappy ground bar.